Fendt South Africa has extended its product offering with the latest generation of the Fendt 200 VFPS Vario specialist tractor series, which comes with the intuitive FendtONE operating concept, making it the first specialist tractor with a fully integrated terminal. There are added innovations like the step-less Fendt Vario drive, demand-led power boost concept Dynamic-Performance and an all-new design. The new technology on the Fendt 200 VFPS Vario enhances precision and everyday efficiency and has been inspiring customers worldwide for the past 11 years.

South Africa is a land of fantastic fruit, and is one of the main fruit-producing countries in the world. More than 50% of South African agricultural exports is fruit. Figures from Fruit South Africa indicate that more than 4.7 million tons of fruit are produced in South Africa each year, of which 59% is exported, 28% is used for processing and 12% sold locally.

“We at AGCO believe that specialist farmers in South Africa that have operations focused on exporting their produce ought to be able to compete with their international counterparts from a mechanisation point of view as well,” comments Ryan Clark, Product Marketing Manager, Lower Horse Power Tractors, Africa. “The technological solutions and innovations in these modern specialist tractors provide farmers the very best in productivity, efficiency and results-driven farming for the best job in the world,” asserts Clark.

The Fendt 200 VFPS Vario series of specialist tractors includes five models (Fendt 207 Vario, Fendt 208 Vario, Fendt 209 Vario, Fendt 210 Vario, and Fendt 211 Vario), with outer widths ranging from 1.07 m to 1.68 m. The maximum power range of this series is between 79hp (58kW) and 124hp (91kW), in accordance with ECE R120. All models are available as Power, Profi and Profi+ versions.

The three-cylinder, 3.3-litre AGCO Power engine meets emissions Stage V, with a diesel oxidation catalyst (DOC), diesel particulate filter (DPF) and selective catalytic reduction (SCR), but without exhaust gas recirculation. There are also maintenance-free hydraulic tappets built into the engine, which reduces the total cost of ownership. The electronically-controlled Visctronic fan runs just when it is needed.

“It works quieter and saves fuel,” mentions Frans Cronje, Regional Sales Manager for Fendt, AGCO South Africa. Cronje continues: “Compared to the previous model, the new Fendt 200 VFPS Vario boasts a total of 33 innovations, with 21 of these packed into the standard Power configuration. Every farm is different, and therefore there are the three Power, Profi and Profi+ configurations, combined with the flexibility of over 160 options, as well as 70 tyres and tracks to tailor the tractor perfectly to specific requirements, and that makes this a very special tractor for the specialist farmer.”

World-leading FendtONE operator workspace

The Fendt 200 VFP Vario’s new suspended four-pillar cab is more spacious and offers more headroom. In its basic configuration, it meets all the standards of a cab with protection Category 2. The filter system can also be upgraded to protection Category 4 in accordance with EU standard EN15695, with protection against dust, liquid fertilisers and vapours. The Fendt 200 VFP Vario meets all requirements for plant protection use and keeps the operator safe. Once the work is complete, the filter system can be easily converted back to Category 2 via the terminal screen. There is a new control console with multifunction joystick for easy and intuitive machine operation.

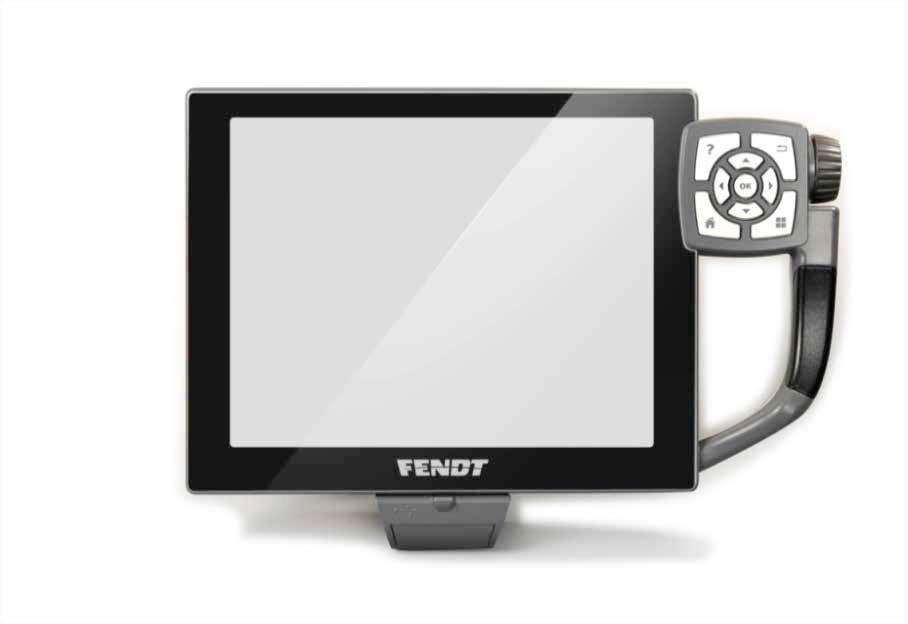

The FendtONE operating concept includes an optional new control panel on the side with the multifunction joystick, crossgate control lever and 12″ terminal. In the Fendt 200 VFP Vario, the 12″ terminal is built into the roof liner above the windscreen. The 10″ digital dashboard is located at the front of the steering column. Its indicators include the driving speed, engine speed and fluid levels. The digital dashboard can be operated via the push-dial on the steering column.

Farming operations that own the Fendt 200 VFPS Vario Power models can enjoy a digital display area for the first time, with the 10″ digital dashboard fitted as standard. This makes it much easier, faster and clearer to configure engine and gearbox functions and working hydraulics, among other things. The multifunction joystick opens up new control possibilities in the Fendt 200 VFP Vario Power.

“Now you can proportionally control two valves and adjust the active speed of the cruise control, all with the dial on the joystick. The joystick has buttons ready to be assigned to additional functions, like the hydraulics,” points out Cronje. “Then there is the ingenious headland management Fendt TI, the ISOBUS 200 control system and the full Fendt Guide lane-guidance system (from Profi+), with all the software tools from Fendt Contour Assistant to Fendt Section Control and Fendt VRC (Variable Rate Control).”

New Self-Steering and Variable Rate Application systems with centimetre-accuracy on the Fendt 200 Vario Profi+

With Fendt 200 VFPS Vario Profi+, farmers can now boast the complete range of smart farming solutions adopted from the Fendt 700 Vario. In addition to the Fendt Guide lane guidance system (formerly VarioGuide), Fendt 200 Vario Profi+ is also available in the Agronomy module of Fendt Task Manager and Fendt Task Doc (formerly VarioDoc Pro).

With Fendt Task Manager, the farm manager can create job orders in the office or on the move and send them straight to the machine. Use Fendt Task Manager together with Fendt Guide and the RTK correction signal, and the Fendt 200 VFP Vario can drive down rows with centimetre-accuracy and process the fields even more efficiently.

With Fendt Guide, the machine operates steadily and accurately, even in poor visibility. Fendt Guide lets the tractor and equipment work at full capacity, because the Fendt 200 VFPS Vario stays on track without active steering inputs, even at night or with large working widths. With Fendt Guide, the tractor automatically maintains the ideal line so that the operator can concentrate fully on the implement and the job at hand. There is less overlapping and, depending on the work, farmers can realise savings of between 3% and 10%. Cronje comments: “When cover spraying, you can avoid going over the same spot twice. Once the work is done, Fendt Task Doc can automatically send the job order to the office. This makes it easier to document and measure the work carried out during the day, the entire season, and even by specific operators.”

The 12″ terminal can show various machine functions, lane guidance options, ISOBUS functions and attachment functions. The display can be customised to suit the application. In special crops like wine, fruit or hop cultivation, a tracking system on the tractor makes the work much easier, especially when first planting. “It’s great for arranging ridges and plants with centimetre-accuracy and getting the follow-up work done more easily and efficiently,” adds Cronje.

Smart assist is a real benefit for repeat processes, especially headlands. The Fendt TI headland management system saves up to 1 920 daily hand movements in 160 turns. Both manually at a standstill and while driving, the tractor can record all the functions as a sequence and save them in the terminal. All it takes is a touch of a button to activate automated sequences when entering and coming out of the headland. Five triggers (route, time, front power lift, rear power lift and manual) and 13 function groups help control an impressive total of 74 functions.

Work or operator profiles can be stored for perfectly adjusted equipment and controls, even with different drivers working on the same machine. These work profiles save each implement with its own settings. This saves time and reduces complexity from having to enter the settings each time. Even if you have different drivers, they can then work efficiently and optimally without having to adjust any settings or parameters every time.

Fendt’s Dynamic-Performance

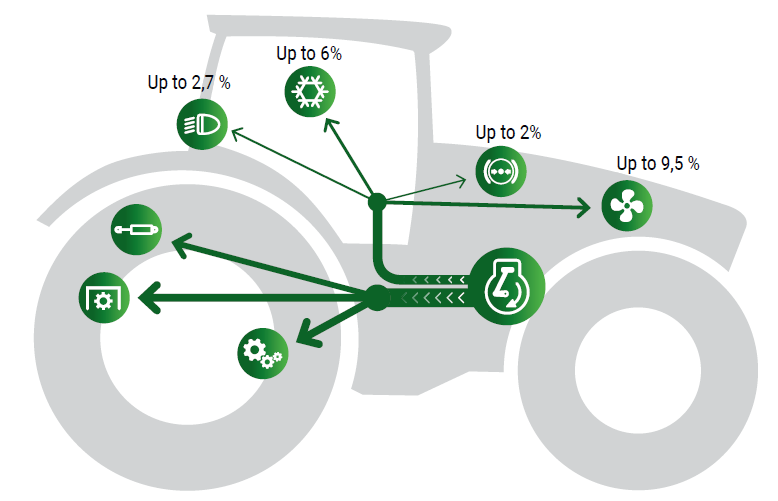

Lightweight and powerful, the innovative power-boost Dynamic-Performance (DP) concept on the Fendt 200 VFPS Vario releases 10hp more power on demand, just when it’s needed. It is not tied to driving speeds or special operational tasks, but works purely independently.

Typically, the engine power of tractors is distributed across numerous power consumers – such as the PTO, hydraulics, engine fans and air conditioning. The DP power boost system detects when certain components need more power and then provides a boost with smart control. The DP power boost concept comes into action at a standstill, but also during transport and field work. Fendt Dynamic Performance comes into use on the Fendt 200 VFPS Vario when towing a vegetable harvester or using an applicator sprayer on a steep slope, depending on the power consumers at the time. “The 10hp extra boost of power from the Fendt 200 VFPS Vario is fantastic for farmers who need a powerful narrow-gauge tractor with additional power reserves,” asserts Cronje.

The built-in extra power of the Fendt Vario comes from always working sensitively at the perfect speed and optimum efficiency to achieve maximum area coverage. It taps into power reserves that powershift gears just cannot match. Cronje comments that “Independent tests reveal this saves up to 7% in working hours and up to 9% diesel compared to shift gears, depending on the type of farm.”

The Fendt 200 VFPS Vario boasts an impressive precision electronic controlled rear linkage package, with lift capacities of 2 775kg to 4 204kg force depending on the model. This guarantees that even the heaviest mounted implements can be operated to their full extent, while shock load stabilising, which comes as standard, ensures quiet driving without stressful vibrations. From the cab, the operator has an excellent view of the lower links, ball-type coupling and drawbar pin. The rear of the tractor has practical advantages such as an unrivalled one-handed lower-link latch and spindle adjustment of the lift rods with an integrated scale.

The Fendt 200 VFPS Vario boasts an impressive precision electronic controlled rear linkage package, with lift capacities of 2 775kg to 4 204kg force depending on the model. This guarantees that even the heaviest mounted implements can be operated to their full extent, while shock load stabilising, which comes as standard, ensures quiet driving without stressful vibrations. From the cab, the operator has an excellent view of the lower links, ball-type coupling and drawbar pin. The rear of the tractor has practical advantages such as an unrivalled one-handed lower-link latch and spindle adjustment of the lift rods with an integrated scale.

A front power lift with vibration dampening is available for operations that want to get things done faster and more efficiently. “Now farmers can get two jobs done at the same time, cutting down on time and cost,” mentions Cronje. The front linkage on the Fendt 200 VFPS Vario has a maximum lifting capacity of 2 380kg to 2 540kg and offers load relief control technology for balanced implement operation, allowing the front linkage to operate to a defined downward field pressure, and is adjustable via the in-cab terminal. Cronje points out: “The load relief technology is perfect for mowers or mulchers attached to front of the tractor, for example, because the implement follows the ground contour precisely at a constant height. There is no need for conventional relief springs, because the weight is transferred from the implement to the front axle, simultaneously increasing wheel traction, which prevents slipping in wet conditions or drifting on hillsides.”

When it comes to hydraulic power, the Profi model of the Fendt 200 VFPS Vario is equipped as standard with a powershift control pump (71 litres) and a fixed-flow pump (33 litres), providing farmers with an impressive 104 litres per minute of overall hydraulic oil flow or a working pressure of 200 Bar. “The high pump capacity keeps the engine speed low, which saves fuel and power effectively, even during demanding work.” Comments Cronje. The Power variant has two 42-litre + 33-litre fixed-flow pumps as standard, with a total capacity of 75 l/min with summation.

The Fendt 200 Vario has up to seven double-acting auxiliary hydraulic valves, with up to four connections in the rear, three connections on the centre-right and two connections on the centre-left. Exact oil flow and time can be adjusted on all valves via the in-Cab terminal, and controls can be assigned to different controllers in cab, allowing the operator to adjust the controls for maximum comfort, ergonomics and efficiency when carrying out long and repetitive tasks on the farm. Attaching and detaching front implements with their own hydraulics is easy, with a double-acting valve in front panel of the front hitch. External controls are fitted to the exterior of the tractor on both sides, and on the front and rear, allowing operation of the hydraulics and PTO, making attaching and detaching implements a one-person job.

The self-levelling front axle suspension, with 80mm suspension and built-in anti-roll control, guarantees optimum traction and increases wheel-to-ground contact by up to 7%. The integrated anti-roll control and the ever-powerful Vario drive delivers the best machine and operator safety, even on slopes or when using front loaders. Anti-roll control guarantees a high degree of stability and operating safety, especially when working with heavy implements or loaders on slopes.

The Fendt 200 Vario is based on a robust monobloc design, suitable for a permissible overall weight of 4 800kg to 7 500kg. For maximum operating safety, the Fendt 200 Vario slows itself down via a large-sized wet ring piston brake with brake servo. This four-wheel brake with all-wheel drive combines safe deceleration on all four wheels and long service life with short pedal travel and effort.

The automatic 4WD and the rear multi-disk differential lock function is steering and speed-dependent. This automatic system is very effective on the headland, as an example. Both functions are switched on or off depending on steering angle or forward speed. The result is ultimate tractive power and soil protection, with full manoeuvrability. Cronje points out: “The superior value retention of a Fendt 200 VFPS Vario is a solid building block for its overall economic efficiency because it costs less per hour in the long run, in addition to its cutting-edge solutions. It remains a great investment, even after many years, and has the superior performance and working comfort of the big Fendt tractors that South Africa has already come to know and love. The intelligent combination of these systems guarantees maximum performance, machine safety, and the most advanced precision technology that South Africa has ever seen in this class of specialist agricultural tractors.” mentions Cronje.

In support of the farming community, Fendt has a nationwide dealer network covering the whole of South Africa, offering service, sales and support. For further information, and to get in touch with your closest dealer, visit www.fendt.com/za.