Sorghum beer in Africa is big business, especially for breweries like Chibuku Products Ltd (CPL) in Malawi. CPL has four brewing plants and a market share of 99%, making it the largest brewer of sorghum beer in the country. And it’s this strong foothold in the industry that makes CPL an important customer for Nampak Malawi.

“CPL and Nampak Malawi have a long-standing relationship that spans more than 50 years,” says Chrissy Nyirenda, Commercial Manager of Nampak Malawi. “We have been their carton supplier of choice for their products for much of our shared history. If CPL sneezes, Nampak catches a cold – that’s how deeply intertwined each of our business interests are.”

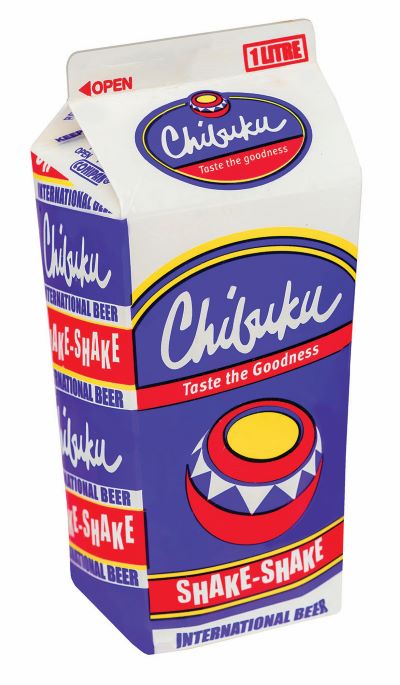

Nampak Malawi currently supplies CPL with a conical carton packaging solution for its fresh sorghum beer product, Chibuku Shake Shake. This particular carton was a finalist at the recent AfriStar 2022 Awards. However, while the conical carton has enjoyed a lot of success recently, it was briefly shelved by CPL to trial a returnable plastic bottle solution.

The returnable plastic bottle experiment

CPL was once owned by a different company and it was under this management team that the brewery took the decision to test the market with a returnable plastic bottle solution for its hugely popular fresh sorghum beer product, Chibuku Shake Shake. The previous owners saw this as an alternative to one-way cartons that would allow the business to save on packaging costs by reusing the same bottles over and over.

In this system, the journey of the new one-litre returnable bottles would see them leave the brewery on their first trip to retailers such as bars, beer halls and taverns. After finishing their first Chibuku Shake Shake, customers could return the bottle to the retailer and either receive a discount on their second beer or claim the bottle deposit. The bottles are then stored by the retailer until a CPL delivery truck arrives to collect the used bottles. Once returned to the factory, the bottles are washed, and quality checked before they re-enter the brewery’s filling line. The bottles are then given new caps and labels ahead of their next trip.

This level of post-production processing in CPL’s brewing operations required the company to make additional investments into bottle washing lines. The brewery also hired more staff to quality check the bottles to see if they met hygiene standards before being re-introduced into production. Each bottle needed to make at least 10 trips to ensure that this new packaging strategy was feasible.

In theory, a returnable plastic bottle system appeared to be the right choice for CPL’s management team in terms of cost saving. However, the brewery ran into a couple of challenges that it hadn’t anticipated with this type of packaging for its sorghum beer.

Mounting inefficiencies and post-production costs

The process of reintroducing the used plastic bottles into CPL’s filling line required the company’s delivery trucks to collect the used bottles from retailers during their fresh beer delivery runs. This meant that the drivers couldn’t simply drop off the new beers and head to their next delivery stop; they would have to load the empty used bottles as well. This made the delivery process inefficient and cumbersome, as the drivers had to first offload the used bottles at each stop before they could reach the fresh beers stored at the back. The used bottles would then need to be repacked into the truck.

In addition to an inefficient delivery process, the washing and sanitising of the collected bottles increased the brewery’s post-production costs. A bottle washing line was installed in each of CPL’s four brewing plants, which required chilled water, compressed air, detergents, additional energy, and staff to operate and complete the quality checks.

CPL aimed to achieve 10 trips from each bottle. Based on conservative estimates, CPL was experiencing a bottle attrition rate of 15% per trip. This means that by the fifth rotation, just over half of the original bottles were making it back to the brewery to be refilled.

Retailer admin

Returnable bottles also created unnecessary administrative burdens for the retailers. When customers purchased a bottle of Chibuku Shake Shake, those that returned the bottle would either receive a second beer at a cheaper price or reclaim the deposit fee. However, retailers had to keep track of the bottles they sold, and the corresponding deposit fees paid in order to properly refund customers. This required retailers to have a float of cash for the exact amount needed to refund deposits, adding an unnecessary administrative task to only one product on their shelves.

Additionally, retailers stored the used bottles until they were collected by the brewery. Because of the option to return, the bottles now had an ascribed value, and this made them vulnerable to theft. As a result, retailers had to lock up the bottles and wait for them to be collected. This can take up valuable storage space and create logistical challenges, especially for smaller shop owners. Also, the leftover residue in used bottles can develop an unpleasant sour odour after a couple of days.

It’s all these factors that started to make retailers less enthusiastic about a returnable bottle system and ultimately led to push back from bar and tavern managers.

Consumer perception

The biggest challenge CPL faced was consumer perception when it came to the hygiene of the returnable plastic bottles. While the bottles were cleaned and sanitised before reuse, there was still an unease among some consumers as to where the bottles had been and what they had stored. The appearance of the bottles also didn’t help as after one or two trips, the once new and shiny plastic started to show scratches and scuff marks. This led to a loss of trust in the product and customers called on CPL to change back to the conical carton.

“We as Nampak visited the different bars and beerhalls to talk to customers about the returnable bottles and they were deeply unhappy with the packaging choice,” says Nyirenda. “The low sales and customer feedback told us that the market wanted Chibuku Shake Shake to return to cartons.”

Switching back

It’s important to note that CPL was bought by the Bowler Consortium in 2018. The decision to trial the returnable bottles and buy new equipment had been made under previous management, who were unable to see the trial through. Due to the significant investment in the experiment, the new owners decided to move forward and give the returnable bottles a chance. However, by 2019, Gerald Bowler, Managing Director of CPL, took the decision to listen to the market and scrap the returnable bottles thus switching back to cartons.

By the end of the returnable bottle experiment, CPL had lost three quarters of their fresh sorghum beer sales as consumers voted with their wallets. However, since the re-introduction of cartons in 2020 under Bowler’s leadership, Chibuku Shake Shake sales have increased phenomenally year-on-year.

“By 2020, Nampak Malawi’s carton sales had dropped by over 300%, however by 2022, we were on the road to recovery with a 220% increase in unit sales,” says Nyirenda. “The turn around has been positively overwhelming, and we couldn’t have asked for a better result. Brewery sales are now trending towards an all-time record high.”

The recent sales numbers have demonstrated cartons to be trusted and well-loved by sorghum beer consumers in Malawi. Cartons are one-way and tamper-proof, meaning they cannot be tampered with and resealed once opened. This helps to ensure the hygiene and safety of the product, guaranteeing that what goes into the carton at the brewery is the only thing that comes out of the carton when the consumer opens it. One beer, one pack, one time.

In comparison to its dairy and fruit juice cartons, Nampak uses a lighter board for its conical cartons. Dairy and fruit juice are long life products that need a thicker board to ensure they stay protected. The lighter board is more economical and suits the short five-day shelf life of fresh sorghum beer. This is a vital consideration for breweries as sorghum beer drinkers are often price sensitive. This makes the conical carton the ideal fit-for-purpose packaging solution for the industry. And while the carton may be considered a single-use product, it is re-used to plant seedlings and as a safe alternative to firewood, as it doesn’t release any harmful emissions.

“Nampak Malawi has been a close and strategic partner of CPL’s for a number of years now,” says Gerald Bowler, Managing Director of CPL. “We continue to work with Nampak Malawi to ensure we have the best packaging solutions for our products that not only work in the best interests of our business, but also meet the needs and preferences of our consumers.”

“The conical carton has stood the test of time with over 18 billion produced since it was introduced in 1954,” says Shaun Du Plessis, Managing Director of Nampak Zambia and Malawi. “Following the AfriStar 2022 Awards earlier this year, we are proud to say that we provide CPL with an award-winning product. Nampak Malawi and CPL picked up a finalist award for the Chibuku 1-litre conical carton in the Beverages category.”

The conical carton was developed specifically to package fresh sorghum beer and is the only pack in the world with a chimney vent. It has a wider bottom and narrower top that allows fermentation to continue once packaged and on the shelf.

“The conical carton is a fit-for-purpose packaging solution for the sorghum beer industry that has stood the test of time,” says Du Plessis. “We’re pleased to see the phenomenal success CPL has had in recent years with Chibuku Shake Shake as they took the decision to listen to their customer and give them what they want.”

Overall cartons are the preferred packaging choice for fresh sorghum beer in Malawi. There are unfortunately far too many variables when it comes to returnable bottles that make them problematic for the brewery, retailers and consumers. Cartons have proven themselves to be a sustainable, hygienic and trusted packaging choice for the industry as seen in the current sales.