The BMG team works closely with sugar mill engineers in the industry’s off-crop period each year, to refurbish and relace worn components in preparation for high productivity in the upcoming season.

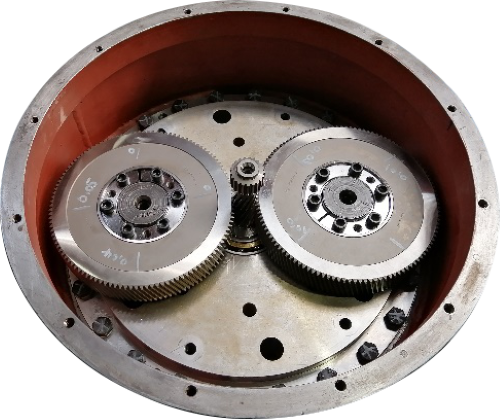

Dorstener gearboxes have been used on diffuser drives, mill drives and feeder tables for many years and three of these planet carriers recently needed to be replaced, due to excessive bearing journal wear and cracking.

“In spite of tight time restrictions before the seasonal start-up of the mill, coupled with manufacturing challenges, BMG has designed, fabricated and installed new carriers, reducing the normal 24-week delivery period to only four weeks, with cost savings of about 7,5 times that of the OEM,” explains Mike Cooper, General Manager- Engineering, BMG. “Carriers are normally manufactured by Dorstener from cast iron, which is extremely difficult to repair. In this case, there was the additional problem of bores positioned close together, with virtually no wall thickness between the bearing journals, which was where the cracking had occurred. Because of the harsh operating conditions of the mill and the high torque load of these units, we decided replacement was the preferred option over refurbishment.

“These planet carriers were re-engineered and fabricated out of 355WA steel plate, which is not only stronger than the original cast iron units, but also allowed us to manufacture these carriers in a far shorter lead time, of three weeks.

The team was on a tight deadline to have drawings and designs approved to ensure highly accurate dimensions for a perfect fit and clearances and to accommodate the gear mesh.

Welding challenges to maintain structural rigidity of the system, were overcome by machining interlocking tabs in the top and bottom main plates, as well as in the webs and side rings, to ensure a more precise assembly for welding, with less distortion. The webs and side plates were welded to the bottom ring and the entire assembly was then fitted fit onto the top ring, for welding into place. Slots were later filled with weld, so that the webs form an integral part of the structure.

BMG’s specialist services to the sugar sector include bearing and gearbox inspection, bearing and chain refurbishment, large size bearing assembly and alignment and balancing, as well as customised product design.

The company’s mobile field services team conducts breakdown and routine maintenance on plant and carries out trouble shooting to ensure the highest level of plant output and reliability.

BMG’s total plant maintenance solutions service is geared to optimising productivity and enhancing process plant operating reliability to make a difference to the efficiencies of every plant.