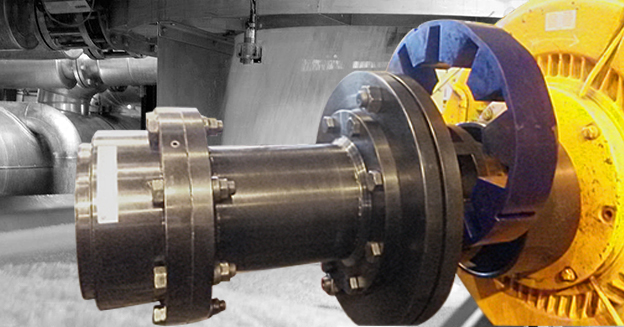

This is a special Timken Quick-Flex coupling, with spacer and shear pin assembly, designed especially for the sugar industry. BMG has the capability to manufacture and modify all configurations, to suit exact application requirements.

BMG works closely with chief engineers in the sugar industry, providing engineering solutions and technical services, to enhance production efficiencies at every mill and refinery.

“The company’s extensive range of quality branded components, engineering solutions and technical services are geared specifically for every industry, including the sugar sector,” says Carlo Beukes, BMG’s business unit manager, Power Transmission. “BMG’s specialist services to the sugar sector include bearing and gearbox inspection, bearing and chain refurbishment, large size bearing assembly, alignment and balancing, as well as customised product design. BMG also offers a troubleshooting and maintenance service, condition monitoring and training.

“BMG’s team of mobile technicians conducts breakdown and routine maintenance on site. This team carries out troubleshooting at sugar mills and advises on possible productivity improvements, to ensure the highest level of plant output and reliability.

“The company launches new products and advanced systems, to meet exact industry requirements, which are constantly evolving. Important power transmission components for sugar mills and refineries include maintenance-free, heavy-duty engineering couplings – Timken Quick-Flex (QF) and Vulkan GBN heavy industrial couplings – designed for efficient performance, low maintenance and extended service life in harsh operating conditions. These components extend from light–duty, high speed/low torque drives, to extremely heavy–duty, low speed/high torque drives.

“The overall features and benefits of these two couplings are similar, with one major difference – the QF coupling is ideal for shaft sizes up to 232 mm, while the GBN series accommodates bigger shaft sizes, up to 600 mm.

“Through BMG’s assistance with careful and accurate product selection, correct installation and appropriate care of couplings, substantial savings can be made in reduced maintenance costs and minimal downtime. These procedures also increase the L10 lifetime of the product.”

The primary purpose of couplings is to transmit torque from a driving shaft to a driven shaft and to accommodate shaft misalignment within the drive. Couplings also dampen vibration, torque fluctuations and torsional shock loads, even in arduous applications.

Timken Quick-Flex couplings consist of two steel coupling hubs, which are attached to the drive and driven shaft. A urethane element wraps around the two hubs and provides a simple, yet effective, drive mechanism. The only spare part required, is a standby element that can be quickly changed when necessary.

Inserts, which are resistant to chemicals, are manufactured from different grades of urethane to suit various industries. The red insert is suitable for most high-speed applications with high levels of vibration, the stiffer blue insert is designed for higher torque applications and the black insert can withstand extremely high torque requirements, replacing grid and gear couplings.

An advantage of these flexible couplings over conventional units, is direct replacement with virtually all comparable sized couplings. Quick-Flex couplings require no lubrication and are also easy to install and maintain. Due to the high torque capacity of this range, the selected QF solution is often smaller than the replaced coupling. This leads to a major weight-saving on the drive and also reduces stress on other components.

Three different elements per size are available, each with a different torque rating. The flexibility of this design makes the range suitable for many applications – from high speed/low torque/excessive vibration drives, to a low-speed/high-torque application.

Important features include excellent balance, allowing for high speed applications up to 12 000 RPM, low maintenance with no lubrication requirements and substantially reduced downtime. These couplings accept angular misalignment up to 2º and parallel shaft displacement up to 7.92 mm.

Once the two coupling hubs, insert and cover have been installed and aligned for the first time, the coupling hubs do not need to be moved again for the life of the equipment. Unlike standard jaw-type or gear couplings, there is no metal–to–metal contact between the hubs. This prevents any possible damage to the ironware during an element failure. The urethane insert can be easily changed, without moving the hubs or shafts and no re-alignment of components is necessary.

Quick-Flex couplings are compatible with shaft sizes from 10 mm to 286 mm and can accommodate a wide speed range – from below 100 rpm, to 12 000 rpm. Torque ratings range from 43 Nm to 188 795 Nm, depending on the selected element and cover design based on the blue element specifications.

BMG’s Vulkan Flexomax GBN maintenance-free couplings are suitable for applications that include low speed shafts of machinery driven by electric motors. For example, sugar mills, conveyor belts and tippers, as well as all machinery with high loads. These compact couplings allow for compensating axial, radial and angular misalignments and also protect the drivetrain from shock loads.

This range has a modular design that enables the integration of brake discs, pulleys, shear devices and spacer shafts within the coupling. Radial removability of the coupling elements is possible, without having to move the connected machinery. No lubrication is required during assembly or disassembly.

These torsional flexible couplings have a maximum torque of 1 288 800 Nm and shaft diameters up to 600 mm. This range is equipped with specially designed elastic elements, which work in compression, allowing for maximum torque transfer, heat dissipation and product longevity. These polyurethane elements are resistant to water, oil and dust.

Vulkan Flexomax GBN couplings are available in 16 sizes with nine designs and have customisable options to meet the requirements of restricted applications.

BMG supplies a wide range of products, selected especially for the sugar industry throughout Africa. These components include carrier and diffuser chain, knife and shredder bearing housings, custom sprockets and gear couplings, as well as steam gaskets, heat exchangers and hydraulic tools. Diffuser and mill gearboxes, in addition to mill lubrication and hydraulic systems, form a critical part of this range.