SKF is an invaluable partner to the global food and beverage industry, offering food safe compliant technology, product and systems solutions that contribute significantly to high machine availability and uptime for ultimate sustainable business profitability.

The fact that there simply is no compromise when it comes to the production of safe food is supported by ever-stringent regulations placed on this market sector. SKF is constantly developing new technologies that give rise to a range of superior quality Food Line bearings, seals, lubricators and lubricants which include corrosion resistant properties and feature SKF’s proven relubrication-free technology. Providing unparalleled bearing performance in wash-down environments, these leading-edge products reduce maintenance costs, increase machine availability and deliver environmental benefits too!

In addition to the food and beverage products being produced or processed (e.g. acidic citrus fruit, abrasive bakery ingredients, etc.), the stringent cleaning requirements of this environment also have a negative impact on equipment. Food safety and hygiene regulations demand frequent high-pressure wash-downs of machinery with abrasive cleaning agents, resulting in component corrosion, grease wash-out and seal damage. This increases the risk of product contamination resulting from lubricant leakage.

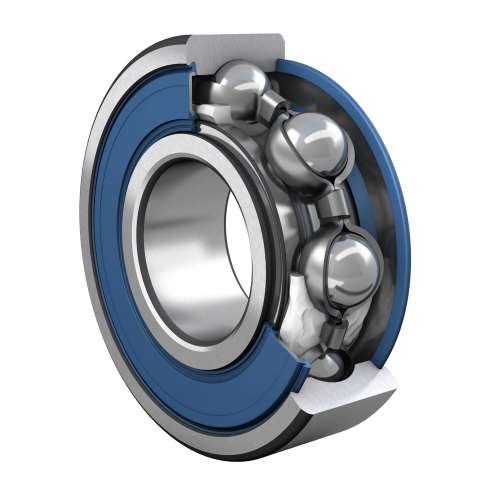

SKF’s new Food Line stainless steel deep groove ball bearings (DGBBs) comply with all food safety requirements. The bearings’ inner and outer ring, rolling elements, cage and backing plate for seals are manufactured from stainless steel. This ensures high corrosion resistance for virtually any food and beverage manufacturing environment. The synthetic rubber seal compound complies with US Food and Drug (FDA) and European Community (EC) category 3 recommendations. The bearings are also pre-lubricated with high quality conformant NSF category H1 registered grease.

High temperature DDGB bearings from SKF are ideally suited to baking applications. These units perform optimally in temperatures up to 350°C owing to a fully crowned, pure graphite cage that can withstand extreme heat. The cage permits just enough contact between the ball and cage to create a fine powder which coats the rolling elements of the bearing. In addition to eliminating metal-to-metal contact, continued relubrication is no longer required, reducing costs in lubrication purchase as well as minimising downtime.

SKF’s Food Line Compact Beverage units offer the perfect solution for applications requiring a high load capacity but a compact housing; typical for conveyors in the beverage industry. Designed with a closer bolt distance, these bearings incorporate SKF’s relubrication-free bearing technology, high sealability and high-efficiency grease.

SKF recommends the Food Line Y-series bearings for applications in wet, abrasive and contaminating environments. Owing to their innovative design, these lubrication-free units help to eliminate wash-down related corrosion problems, premature bearing failure and environmental impact.

Ultra-reliable and accurate lubrication is fundamental to high equipment availability. SKF System 24 gas-driven single point automatic lubricators (LAGD series), can be adjusted to ensure delivery of the correct quantity of lubricant is to the lubrication point during a pre-determined time. This presents accurate control of the amount of lubricant supplied. Featuring a flexible dispense rate from one to twelve months and an intrinsic safety rating (ATEX approved for zone 0), these lubricators are suitable for numerous types of equipment including pumps, electric motors, fans, blowers, conveyors and chains.

Food safety management systems such as Hazard Analysis & Critical Control Points (HACCP) require the use of lubricants registered as acceptable in the case of incidental food contact. Here too, SKF has the solution in the form of clean, non-toxic bearing grease, SKF LGFP 2. This NSF H1 registered, Halal and Kosher certified grease is based on medical white oil using an aluminium complex soap. Boasting excellent grease life and high water and corrosion resistance, this bearing grease is suitable for use in bakery and food processing equipment, conveyor bearings, as well as wrapping and bottling machines.

[…] Source link […]

Comments are closed.