The new Spirit 7200 complements the AVR Spirit family with a drawn, two-row offset potato harvester. In essence, it is a further development of the Spirit 6200.

Since chemical haulm destruction is increasingly prohibited and mechanical haulm topping is an issue, one of the challenges was deciding how to handle these conditions in a haulm web machine. The Spirit 7200 is a response to this, integrating an additional haulm separation system in the form of a haulm roller just upstream of the in-line pintle belt. In addition, a trash web under the haulm web ensures that potatoes that “dropped” late remain in the machine and that any haulm that does fall through the haulm web is removed.

There are other features in the large tire sizes, the option of having twin tires, a pintle belt unit, bunker, and control of the machine (ISOBUS).

Cleaning modules

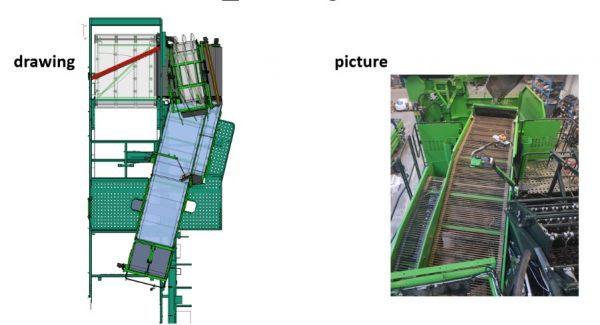

After being picked up by the digging unit, the first sieving takes place on the digging web, which has a width of 1,650 mm. This is fitted with hydraulically powered eccentric vibrators. Then there is the combination of haulm web and sieving web – as these operate so close to one another, the drop height from the digging web to the sieving web has been kept to a minimum. At the transition from the sieving web to the pintle belt, a haulm roller provides additional haulm separation. The haulm roller is easy to adjust in intensity by moving it farther under or away from the sieving web. A potato-friendly transition is ensured as the haulm roller is followed by a soft pintle belt.

On the in-line pintle belt, the potatoes are conveyed to the transversal pintle belt by a triple retaining roller. If desired, the transversal pintle belt can be placed at a greater or lesser angle. Height adjustment from the picking-off table offers the option of quickly adjusting the cleaning capacity.

Different modules are available for the transversal pintle belt:

- The most straightforward variant is a shortened pintle belt with double retaining roller. The picking-off table, with space for six people, does not have a clod web. This machine is also within three meters at full width.

- If stone and clod separation are needed, a three-row or four-row rotary comb is available for the transversal pintle belt. Potatoes are neatly distributed over the picking-off table for a final inspection; stones and clods arrive on the clod web, where a final inspection can also be carried out. The stones and clods are then removed to the ground or to a stone bunker; alternatively, a trash web is also available.

The potatoes are then conveyed into a large seven ton bunker. The hydraulic bend in the picking-off table with automatic control provides for a minimal drop height into the bunker.

What else is new about the Spirit 7200?

AVR Connect

The 7200 is the first two-row harvester that can be equipped with the AVR Connect option. This allows the user to access his machine data online.

Drawbar

The drawbar is fitted with a frame that neatly conceals all hydraulic equipment and electrical cables to the tractor.

Digging unit

The Spirit 7200 is equipped with a quick-change kit as standard. This means that the user can change the digging unit in just a few minutes to allow a different crop to be harvested (e.g., an onion brush).

Mechanical and, as an option, hydraulic depth adjustment are available.

Haulm web/sieving web

Two rows of three haulm retainers ensure that the potatoes stay neatly inside the machine. Here, attention has been paid to ensuring that there is distance between the rows of retainers and that there is an efficient and robust mechanism in place to fold the frame upwards in the event of accumulations.

The haulm and sieving webs are close to one another so that the drop height from the digging web to the sieving web is limited, something that is unique in the market.

At the rear of the machine, under the haulm web, is a conveyor that can remove haulm that falls late and that can return potatoes that fall late back into the machine.

Picking-off table

The picking-off table comfortably accommodates six people. For the best ergonomics, the table has been made as flat as possible.

All functions relating to cleaning at the rear of the machine can be operated easily with a clear keypad or mechanical handles.

Bunker

The fixed bunker is 9.6 m3 in size with a width of two meters and can hold up to seven tons (cf. reference to 7200). A shock absorber is also an option – it can be folded hydraulically and transported on top of the machine.

Tires

The Spirit 7200 runs smoothly thanks to the decision to opt for high wheels (30.5 rim). Different sizes are available (in some cases, dependent on the version):

- 650/65 R 30.5

- 850/50 R 30.5

Twin row-crop tires 380/80 R 38 are available, primarily to help prevent protrusion.

Operation

The machine is controlled by the ISOBUS system. This can save on a screen in the tractor, if desired.

AVR also offers two types of display: Mueller touch 800 and Mueller smart 570.

The 7200 offers numerous automatic functions, for example:

- the adjustable position of the rotor comb

- the automatic level correction

- the automatic back pressure control on the digging unit

- the automatic control of the bend in the picking-off table

- the automatic movement of the bunker floor

- the angle of the pintle belts

- the automatic row following system etc.

In practice

The first two prototypes entered field operation last year and received positive feedback from users. Some ten new harvesters started operation in the field this year. If Interpom takes place on November 28, 29, and 30, it will be the first trade fair at which visitors will be able to view the machine.

[…] Source link […]

Comments are closed.