South African businesses have been under a huge amount of pressure in 2023. Loadshedding has remained an ever-present spectre each day this year except for one, while inflation has only shown signs of cooling recently with a dip to 6.3% in May after a rapid rise for 13 months straight.

The fruit juice industry is no exception to these challenges and has its own industry-specific difficulties. These include a changing regulatory environment around labelling guidelines and the sugar tax as well as logistical problems. Under these conditions, many fruit juice producers will be looking at new ways to cut costs to ensure the viability of their operations.

Packaging and processing are two areas where businesses can consider making smarter decisions to save on costs, while ensuring a high-quality product for their loyal customers. Liquid cartons filled using a hot fill method rather than aseptic can not only cut production costs but ensure seamless operations and promote a premium product to consumers.

Cost-effective production from batch to carton

Hot fill offers fruit juice producers a cost-effective means of production. Aptly named, hot fill is a process of heating the juice before filling the carton. The juice is pasteurised and then cooled slightly to between 80 and 85°C which sterilises not only the juice but also the carton when it is filled. After a holding time of three minutes, the cartons then enter a cooling tunnel before delivery.

One of the most notable benefits of a hot fill process is the price of the machinery. A setup including a cooling tunnel is less than half the cost of an aseptic filling operation and allows for seamless production from start to finish.

When compared to aseptic filling machines, hot fill machines do not require sterilisation at each point in the production process to ensure food safety. The heating of the juice enables a seamless sterilisation from batch to carton that meets all the health and safety requirements for food consumption.

Some producers might argue that hot fill results in a loss of nutritional content and a reduced shelf life. However, the loss in nutritional content is negligible and can be corrected with vitamin and mineral top-ups during the preparation phase. As for the reduced shelf life, fruit juice can be stored for up to 10 months when using hot fill and up to 12 months when using other filling processes – a minor difference of two months.

Adaptability and flexibility

An unreliable electricity supply is a major concern among fruit juice producers with many having to make alternative arrangements for backup power. A major key benefit of hot fill machines for local producers is that they have quick startup times after a power disruption. There is no need to resterilise the machine following a loadshedding block or power outage; it can easily be brought back online with little to no hassle.

In addition to being highly adaptable, hot fill machines allow for a great deal of flexibility when it comes to cartons and consumer preferences. If a producer needs to switch the size of a carton for a product, it is an easy changeover as the same machine can accommodate a variety of carton sizes including 350ml, 500ml and 1L. Unlike reel-fed aseptic machines where each line is dedicated to one carton size only. This hot fill machine flexibility extends to changing consumer demands such as the inclusion of pulp, fibres or chunks when filling cartons as well as flavour changes. Hot fill machines paired with cartons can offer producers a great deal of versatility in a single filling setup.

Fit for purpose

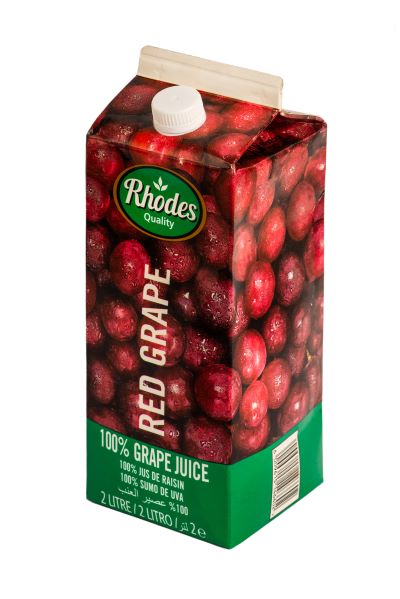

In a world where businesses are competing for the attention of consumers more than ever, products must stand out from the crowd on a shelf full of choices. The flat surface of a carton allows brands to print high-quality, eye-catching designs to draw in consumers and ensure their product is added to the shopping trolley. The extensive surface area also provides brands with enough space to include all the required informative messaging around nutritional value, ingredients, expiry date and other labelling requirement guidelines.

“Cartons provide a versatile platform for making changes to package branding,” says Judith Gale, National Head of Marketing – Private Labels for the SPAR Group. Their flat surfaces offer ample space for creative designs, vibrant colours, and engaging visuals that can effectively convey a brand’s identity and messaging. The use of cartons also allows for easy application of various printing techniques, finishes, and textures, enhancing the overall aesthetic appeal.”

While cartons can create a sense of presence on shelf, they also offer fruit juice packers, supermarket owners and consumers several fit-for-purpose features. The cartons’ design means they can be delivered in high volumes as flatpacks in a single delivery from Nampak Liquid Cartons to fruit juice producers. Once filled, cartons can be packed economically with no spaces between them into delivery trucks due to their square shape.

For supermarket owners, the flat bottom design makes for a sturdy product that sits neatly on shelves. This functionality also extends to consumers who can store their fruit juice carton upright in their pantry or fridge. The tilted gable-top also makes for a user-friendly design that allows consumers to pour a glass of fruit juice conveniently with no spills.

“Overall, the gable-top carton offers a compelling combination of practicality, preservation, and eco-friendliness that suits our fruit juice perfectly,” says Gale.

Made from liquid packaging specific board, fruit juice producers can rest easy knowing that the juice’s contents are protected from UV light and minimal oxygen transfer takes place once filled and sealed. It’s also the liquid board material composition that makes cartons a great single-use sustainable packaging option that is 100% recyclable.

For Pieter Hanekom, Chief Executive Officer of Rhodes Food Group, it’s all these factors and more that make cartons a great choice for Rhodes fruit juices.

“When it comes to selecting the right packaging solution for our products, we need to think about the format, opening, shelf life and affordability,” says Hanekom. “Cartons are a good choice as they not only check these boxes, but they are also easy to transport and speak to our sustainability agenda.”

Liquid cartons paired with a hot fill machine can offer the fruit juice industry a reliable and dependable setup to ensure continued operations in an increasingly volatile business environment. While being a cost-effective option, a hot fill machine with cartons can cater for quick changes overs of juice flavours and carton size. It is these considerations that can contribute to businesses remaining agile during times of substantial change.

[…] Source link […]

Comments are closed.