by Gert Nel, WearCheck divisional manager: transformers, and Corné Dames, WearCheck transformer consultant

Ester oil is a type of insulating oil used in electrical equipment. Natural esters are produced from vegetable oils such as rapeseed/canola. Synthetic esters are produced by the esterification of vegetable oils or animal fats. Esters are often blended with other chemicals to improve their properties. There are several advantages to using natural ester oil over traditional mineral oil, including:

- Esters are

- High dielectric strength: Ester oil has a higher dielectric strength than mineral oil, meaning that it can withstand higher voltages without breaking down.

- It is more stable over a wider temperature range, making it suitable for use in a variety of climates.

- Superior moisture

- No corrosive

Part 1 of this series (Technical Bulletin 85) featured a discussion on the various condition monitoring options for analysing transformer component performance, specifically by determining the degree of contamination of mineral oils and other substances.

Part 2 continues with the testing guidelines of ester oil, including its characteristics in electrical transformers.

3.13 OXIDATION STABILITY

For natural esters, ASTM 6871 does not yet recommend oxidation stability testing methods or limits. Appendix X2 section X2.3.4. of ASTM 6871 states that “oxidation stability requirements and appropriate test methods for natural ester insulating liquids have not been established.” ASTM D6871 deems appropriate all other test methods listed in Table 1 for testing natural esters.

Natural esters are not as resistant to oxidation as mineral oils. For this reason, their application in free-breathing transformers and other equipment (e.g., bladderless conservator design) is not recommended. All practical measures should be taken to avoid continuous, long- term exposure to unlimited air exchange, particularly at higher operating temperatures.

Oxidation occurs only at the surface of the liquid exposed to air, so thin-film exposure is of a more significant concern than the liquid in the transformer tank. It is recommended to minimise the time and temperature that surfaces with thin films of natural esters are exposed to air, including un-tanked core and coils, radiators, heat exchangers, hoses, fittings, etc. For example, the creep dielectric strength of cellulose surface impregnated with a natural ester may be reduced if its surface is exposed to oxygen for sufficient time to cause polymerisation. Different types of natural ester formulations can have different recommended air exposure time limits depending on the type of base oils and the type and amount of oxidation inhibitors.

Exposure to air should also be limited to prevent moisture contamination. If exposure to ambient air over long periods is of concern, refer to the insulating liquid manufacturer’s recommendations on air-exposure limits, detection and maintenance of antioxidants methods, moisture removal, and exposure-prevention guidance for each particular liquid brand.

Natural esters oxidise differently to mineral oils causing polymerisation of the liquid and forming larger molecules that remain in solution, the rate of oxidation is highly temperature dependent with every 10°C increase doubling the amount of oxidation.

Conversely, mineral oil oxidation forms reactive short- chain acids and carbonaceous sludge, which can precipitate out of the oil. Such polymerisation of natural esters in the transformer tank should not impact the dielectric strength of the insulating system. However, suppose the surface of the bulk liquid is exposed to continual exchange of air in the headspace over several years. In that case, the viscosity of natural esters can measurably increase, resulting in the lowered cooling capability of the liquid which may necessitate some corrective action.

ASTM D2112 and ASTM D2440 test methods were developed to evaluate the oxidation stability of mineral oil insulating liquids. These methods note no established relationship between test results and field performance. ASTM D2112 is a control test of oxidation stability of new, inhibited mineral insulating oils for determining the induction period of oxidation inhibitors and to check the consistency of oxidation stability of production mineral oils. Neither was deemed suitable for natural ester insulating-liquid testing. IEC 61125 Method C has been modified and included in IEC 62770 as a method for measuring the oxidation stability of natural ester liquids.

3.14 WATER CONTENT – KARL FISCHER METHOD (ASTM D1533)

Several forms of water may be present in insulating liquids. Free water can be detected by visual examination. This should be visible as separated droplets or as a cloud (turbidity) dispersed throughout the liquid and will result in decreased dielectric strength. When in solution (dissolved) it is not possible to detect visually, and this is usually determined by physical or chemical means. As the dissolved water increases, the dielectric strength will decrease more and more as the water concentration approaches the saturation point.

ASTM D1533, Standard Test Method for Water in Insulating Liquids by Coulometric Karl Fischer Titration, is suitable for the determination of water in insulating liquids and, depending upon the conditions of sample handling and the method of analysis, can be used to estimate the total water content of the sample. The unit of measure of the water is in milligrams/kilogram (mg/kg) or ppm. This test is significant because it can indicate the presence of water even if it may not be evident from electrical tests.

It is important to note the necessity for care when determining the water content in ester oils through Karl Fischer coulometry, given the intricate nature of their chemistry and molecular structure. Ester oils, under typical testing circumstances, have the potential to produce misleading outcomes, manifesting as elevated and unpredictable water content readings. This issue can be effectively addressed through the utilisation of oven samplers (the established approach embraced by WearCheck) or by exercising caution in the choice of reagents and solvent systems applied during the testing procedure.

It is important to note that absolute dissolved water limit values set for mineral oil are not applicable for natural esters. The absolute amount of dissolved water needed to reach a particular saturation point varies by liquid type. Natural esters have significantly higher water saturation values (approximately 15 to 20 times at room temperature) than mineral oil at a given temperature. However, the impact of water content on dielectric strength as a function of percent of saturation is essentially the same for both natural esters and mineral oil.

3.15 VISUAL EXAMINATION

This ASTM Standard Test Method (D1524) for visual examination of Used Electrical Insulating Liquids in the Field gauges the colour or turbidity (cloudiness), indicating the presence of free water or sediment (e.g., metal particles, insoluble materials, carbon, fibres, dirt). If insoluble contaminants are present, valuable information can be obtained by filtering the liquid and identifying the residue. Excessive contaminants can significantly lower the dielectric strength of dielectric coolants and hence its insulation properties.

3.16 GASSING OF INSULATING LIQUIDS UNDER ELECTRICAL STRESS AND IONISATION (ASTM D2300)

The correlation of ASTM D2300 test results with equipment performance is limited, regardless of the liquid type. For specific applications, when an insulating liquid is stressed at high-voltage gradients, it may be desirable to determine the rate of gas evolution or gas absorption under specific test conditions. Natural esters have a lower gassing tendency than mineral oils, well below the lower range, and are generally reasonably negative (gas absorbing). The typical range for a natural ester is-50μL/min to-90μL/min.

3.17 CORROSIVE SULPHUR (ASTM D1275)

This visual test indicates the presence of corrosive sulphur in the liquid. Natural esters naturally do not contain sulphur. Corrosive sulphur is undesirable, as it can lead to premature coil failures.

3.18 POLYCHLORINATED BIPHENYLS (PCBS) (ASTM D 4059)

New natural ester liquids should not contain PCBs. Government regulations may require that electrical apparatus and insulating liquids containing PCBs be handled and disposed of through specific procedures. The procedure to be used for a particular apparatus or quantity of insulating liquid is determined by the PCB content of the liquid. The results of this analytical technique can help select the appropriate handling and disposal procedures.

3.19 FURANIC COMPOUNDS (ASTM D5837)

This method determines the furanic compounds generated from the degradation of the cellulose insulation materials, such as paper, pressboard, and cotton, used in the solid insulation system of electrical equipment. Some of the soluble furanic compounds typically migrate into the insulating liquid. The presence of high concentrations of furanic compounds in samples of the insulating liquid is significant in that this can indicate cellulose degradation from aging or developing fault conditions. Testing the furanic compounds by high-performance liquid chromatography (HPLC – see WearCheck’s TB54) can be used to complement DGA as performed by the test method ASTM D3612.

3.20 LIQUID COMPATIBILITY WITH TRANSFORMER MATERIALS

The transformer manufacturer should ensure that each transformer design and the insulating liquid used are compatible with the ester under standard service conditions. Compatibility should be verified to help ensure that no excessive interaction or reaction occurs between materials in contact with the dielectric coolant. Standard test method ASTM D3455, “ Standard Test Methods for Compatibility of Construction Material with Electrical Insulating Oil of Petroleum Origin” can be used except for Section 8.2.5, “Aged properties for the reference oil specimen.” The reference values should be modified for natural esters. See Table 2 on the following page.

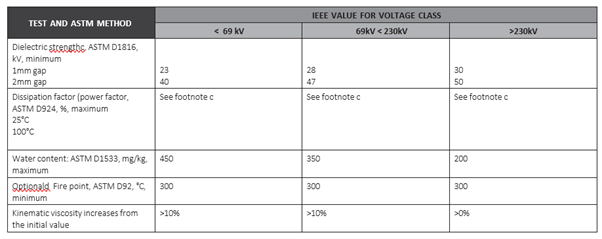

Table 2: Suggested limits for continued use of in-service natural ester liquids (grouped by voltage class) (See IEEE Std C57.152TM)

The test limits shown in this table apply to natural ester insulating liquids as a class. Due to differences in their chemistry, certain values are significantly different than those for mineral See Clause 1 for details. T ypical values for each brand of insulating liquid should be obtained from each insulating liquid manufacturer. If test results, while in compliance with this table, are significantly different from published typical values, it is recommended that the insulating liquid manufacturer be contacted.

- Provisional for >230kV, which are the ratings for transformers In South Africa however, we typically use 33, 66, 132, 275kV, etc.

- When this document was written, insufficient field data analysis was available to provide reliable recommended limit values for the dissipation factor. Users are encouraged to forward data to the IEEE Transformer Committee Insulating Fluids Subcommittee for possible future use.

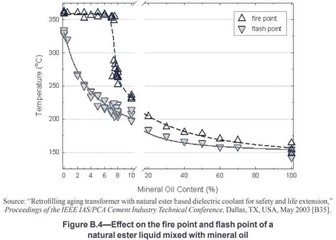

- Most outdoor transformer installations do not require the NEC “Less Flammable” designation; however, it should be noted after retro filling with new natural esters, the fire point of the ester liquid is reduced due to residual mineral oil. For transformers requiring a less-flammable rating or otherwise known to require its insulating liquid to meet a minimum of 300 °C fire point, any sample testing with a fire point below 300°C indicates excessive residual mineral oil and should be investigated. For more information, please refer to Figures B4 and C1

B.4. Relative cooling performance properties

Four cooling-performance properties of the dielectric fluid are often used for transformer design. These include viscosity, expansion coefficient, thermal conductivity, and heat capacity. As viscosity is the most significant, limits are listed within the main clauses of the IEEE guides. However, it is helpful to have the values of the other three properties for thermal design optimisation. Specific typical values of thermal properties for each brand of liquid should be obtained from the liquid manufacturer.

TABLE C.1 – FIRE CLASSIFICATION OF LIQUIDS

From CIGRE Technical Brochure 436, Experiences in service with new insulating fluids, CIGRE WG A2-35, 2010

Natural ester liquids behave differently from mineral oils under stress conditions, and in order to ensure that the insulation fluid operates at peak efficiency, it is essential that regular condition monitoring tests are conducted by a certified laboratory.

UNDERSTANDING THE CHARACTERISTICS OF ESTER OILS IN TRANSFORMERS

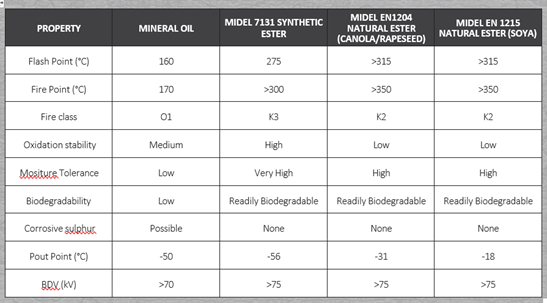

Midel produces transformer insulating oils that are alternative to mineral oils. Below are the typical properties of these oils:

When delving into the realm of transformer oils, a crucial differentiation comes to the fore – that between synthetic ester oils and natural ester oils. These distinct categories play integral roles in various transformer applications, with synthetic ester oils commonly finding their purpose in free-breathing transformers, while their natural ester oil counterparts are typically employed in sealed units. The significance of this demarcation cannot be overstated, as the choice between these oil types can significantly impact transformer performance and longevity.

Synthetic ester oils, renowned for their exceptional properties, are a favoured choice for free-breathing transformers because these oils exhibit remarkable dielectric strength, thermal stability, and oxidation resistance. These attributes collectively make them ideal for applications where the transformer is exposed to varying temperatures and operational stresses. Their synthetic nature empowers them to maintain consistent performance levels over extended periods, thus contributing to the reliability of transformers in demanding environments.

In contrast, natural ester oils come into their own in sealed transformer units. The hermetically sealed nature of these transformers demands an oil type that can uphold stability within confined spaces. Natural ester oils possess exceptional insulating properties and exhibit a lower vapour pressure, ensuring they are well suited to sealed environments. Their inherent biodegradability and eco-friendliness align with the growing focus on sustainable technologies, making them a preferred choice for environmentally conscious applications.

Within the dynamic landscape of transformer technology, WearCheck has observed a remarkable shift in client preferences. A notable surge in the adoption of new ester oil transformers has been witnessed, accompanied by a corresponding uptick in retrofill transformer installations. A striking testament to this trend is WearCheck’s trajectory from monitoring a mere two retrofilled transformers in 2018 to an impressive tally of 418 such transformers in 2022. This evolution underscores the industry’s recognition of the advantages that ester oils bring to the table.

In the journey towards optimising transformer performance, effective communication between clients and testing laboratories assumes paramount importance. While the testing procedures for ester oils are analogous to those for conventional mineral oils, it is considered best practice to assess each oil variant separately. The challenge arises during the diagnostic phase, where the distinct specifications of mineral oil, silicone oil and ester oils necessitate meticulous analysis. Accurate identification of the oil type serves as the cornerstone for interpreting test results and formulating precise maintenance strategies.

COMPARISON OF ETHANE PRODUCTION (PPM) TO OXIDATION (AIR SPARGE, 1 DAY 120°C

From the advanced research workshop for transformers – 2013

Broadly speaking, when considering an oil sample from a newly built transformer intended for ester oil usage, the presence of Dissolved Gas Analysis (DGA) indicators might not be readily apparent. In such cases, the diagnostic approach closely parallels that applied to traditional mineral oil transformers. However, when shifting focus to retrofill transformers, a notable departure emerges. Here, an immediate elevation in ethane, and particularly ethylene, levels become evident. This discernible shift can be attributed primarily to the significantly heightened viscosity inherent in ester oils. Following the retrofill process, these gases experience a sudden surge, subsequently reaching a point of stabilisation over time.

In conclusion, the world of transformer oils is a nuanced realm where the classification between synthetic ester oils and natural ester oils holds significant implications. As WearCheck’s journey exemplifies, the industry is embracing these variants with fervour, recognising their pivotal role in enhancing transformer efficiency and durability. The pathway to effective utilisation, however, rests on clear communication, precise testing, and a profound understanding of the distinct characteristics that set ester oils apart in the realm of transformer technology.

References:

- CIGRE Technical brochure 436, Experiences in service with new insulating liquids, CIGRE WG A2-35, 2010

- Davydov, V.G. “New natural ester dielectric liquids for transformers and other HV apparatus” Proceedings of TechCon 2014 Asia-Pacific,

- 181-200, Sydney, Australia, 2014

- Duy, C.T., Lesaint, A., Denai, and N. Bonifaci, “Streamer propagation and breakdown in natural ester at high voltage,” IEEE Transactions on Dielectrics and Electrical Insulation, vol. 18, pp 285-294, 2011

- EPA OPPTS 835, 3110, Fate, Transport and Transformation Test Guidelines: Ready biodegradability

- Frotscher, R., D.Vukovic, M. Jovalekic, S. Tenhoblen, J. Harthum, M. Schäfer, and C. Perrier, Behaviour of ester liquids under Dielectric and Thermal stress – from laboratory testing to practical use. CIGRE conference 2012, Paris Paper D1-105.

- IEC

- Midel Presentation to Eskom 2018

- Advanced Research Workshop (Spain) 2013

ABOUT THE WRITERS

Corné Dames is a WearCheck transformer consultant. She has 20+ years’ experience in the industry, having previously worked as laboratory manager for a major industrial laboratory group, focusing on transformer health. She has been intrigued by transformer chemistry right from the start of her career, particularly in the analysis of test data.

Gert Nel is WearCheck’s divisional manager, transformers. He has extensive experience and knowledge about transformer maintenance and technology, gained through many decades in the transformer sector. Gert has been with the company since August 2008, starting in the division as a transformer oil diagnostician, and working his way up to divisional manager.

Part 2 of the article can be downloaded as a PDF file via this link: https://www.wearcheck.co.za/shared/TB86.pdf