Since the reveal of the autonomous concept vehicle, Case IH has been evolving the technology and further defining automation and autonomy as it relates to agriculture. The brand has been in discussions with customers around the world to study how this technology can be implemented for maximum benefit in their operations. Now, through its Autonomy and Automation Program, Case IH is researching and piloting autonomous technology in real-life scenarios.

“While the autonomous concept vehicle reveal in 2016 showed the world what’s possible with autonomous vehicles, it was just that — a concept. This working tractor provided a platform for us to start discussions with farmers and the industry about the technology needed for High-Efficiency Farming operations today and in the future,” said Robert Zemenchik, Case IH AFS global product manager. “We’re ready to show how automation and autonomy applies across agriculture and how it can advance the precision farming solutions our customers are currently using on their farms.”

Five categories of

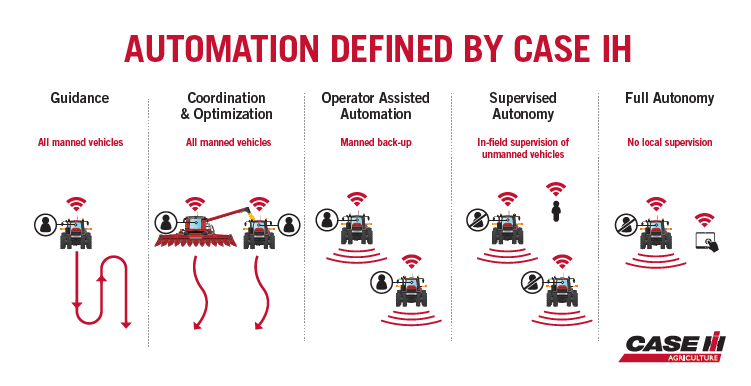

Diverse farming operations around the world require varying levels of automation. Through extensive Customer Driven Product Design research, Case IH found that current and future technology needs fall into five categories of automation for agricultural field applications. The categories and types of activities associated with each include:

- Guidance

- Coordination & Optimization

- Operator Assisted Automation

- Supervised Autonomy

- Full Autonomy

Caption: Case IH is defining new categories of autonomy and automation in agricultural field applications.

Caption: Case IH is defining new categories of autonomy and automation in agricultural field applications.

“It’s exciting to explore the efficiencies that automation and, eventually, full autonomy can bring to each farming operation,” Zemenchik said. “The logic behind the categories is to provide a vision of what’s possible. They are not linear, and a given fleet may even fit into more than one category at a time. Today, many of our customers are already operating in the Guidance and/or Operator Assisted Automation categories.”

The five categories defined by Case IH start with automating specific tasks on a piece of equipment. Case IH led the way by first providing producers automation technology in the 1990’s with AFS AccuGuide™ autoguidance, and it continues today with more advanced solutions, such as AFS AccuTurn™ automated headland turning technology and AFS Soil Command™ seedbed sensing technology.

Caption: Supervised autonomy, one of the five categories of automation as defined by Case IH, allows an operator in one tractor to supervise the operation of a tractor in the same field without an operator.

Caption: Supervised autonomy, one of the five categories of automation as defined by Case IH, allows an operator in one tractor to supervise the operation of a tractor in the same field without an operator.

Researching and piloting autonomous technology in the field

In 2018, Case IH is collaborating with Bolthouse Farms on an autonomous tractor pilot program. The goal of the program is to understand how new autonomous technology can be used and how it meets real-world, on-farm requirements.

“The only way to validate on-farm uses for autonomous technology is, quite literally, with field pilots where farmers use it on their own farm, integrate it into their own fleet and conduct their everyday activities,” Zemenchik said.

As one of the largest carrot producers in North America, Bolthouse Farms is a year-round operation that farms extensive acreage across four states and Canada. The company’s focus on and openness to advanced technology, coupled with their desire to improve productivity, makes it ideal for the pilot for the Case IH Autonomy and Automation Program.

The pilot program will focus first on primary tillage and deep tillage — both highly repetitive tasks Bolthouse Farms conducts year-round — and a small fleet of autonomous Steiger® Quadtrac® tractors pulling a True-Tandem™ disk harrow or Ecolo-Tiger® disk ripper will be used. This will help evaluate autonomous machine control in a variety of tillage applications, soil types, meteorological conditions and sensing and perception activities.

“One of the primary goals is to receive agronomic and operator feedback on the use of autonomous technology in real-world farm conditions so Case IH can further develop and refine our technological control and machine optimization systems,” Zemenchik said. “Additionally, we will be able to learn from Bolthouse Farms what uses they envision for automation and autonomy that we might not have already thought of.”

Brian Grant, Bolthouse Farms vice president of agriculture, views the autonomous tractor pilot program as an opportunity to find new ways to make the company’s operation more efficient and deliver high-quality food for the growing population.

“We’re just now starting to play the ‘what if?’ game — where we’re asking ourselves and the Case IH engineers the questions about what autonomous tractors are capable of,” Grant said. “And the answers to these questions are not ‘if.’ It’s ‘when.’”

Case IH will provide periodic updates throughout the course of the pilot program.

To learn more, visit caseih.com.

Caption: Case IH is defining new categories of autonomy and automation in agricultural field applications.

Caption: Case IH is defining new categories of autonomy and automation in agricultural field applications. Caption: Supervised autonomy, one of the five categories of automation as defined by Case IH, allows an operator in one tractor to supervise the operation of a tractor in the same field without an operator.

Caption: Supervised autonomy, one of the five categories of automation as defined by Case IH, allows an operator in one tractor to supervise the operation of a tractor in the same field without an operator.