Fired heaters are integral to hydrocarbon processing (HP). Specifically designed for the reaction of fuel and air to produce extremely high gas temperatures, heaters transfer this energy to potentially highly flammable process fluids via heat exchangers. They consume large quantities of fuel, produce large quantities of emissions and are a potential safety hazard to personnel and plant. However, they are currently irreplaceable within many HP processes – so they warrant the highest levels of understanding and care in their operation and control.

Recent improvements in burner technology to reduce NOX emissions require closer monitoring of the process, as newer burners often operate under narrower process control conditions than older, larger nozzle diameter gas burners. Demands have also grown on plant operators to improve safety practices, increase plant efficiency and reduce environmental emissions. As a consequence, more accurate and reliable instrumentation is required to support the control of the process.

New and improved technologies are available to control fired heater combustion with ever greater accuracy and reliability, but the correct selection and effective use of these technologies requires understanding of a complex and delicate process. The cornerstones of a well–controlled combustion process is optimized air–to–fuel ratio and efficient fuel consumption. Before analyzer technologies were developed to measure excess air in the products of combustion, fired heaters were run in conditions of high excess air. Although this meant inefficient and costly fuel consumption, it was the only way to avoid the creation of low–oxygen, fuel rich conditions that could lead to a potentially dangerous explosion.

Unfortunately, the reduction of excess air poses a new problem- the process moves to the tipping point at which incomplete combustion takes place. The cornerstones of a well–controlled combustion process is optimized air–to–fuel ratio and efficient fuel consumption.

The introduction of Zirconium Oxide technologies in the late 1960s allowed engineers to obtain reliable and continuous measurements of excess air, enabling them to reduce the air-to-fuel ratio closer to that of the theoretical stoichiometric combustion mix.

The control and safety systems that run fired heaters must therefore perform an extremely complicated balancing act. It is often not enough to just increase excess air levels when incomplete combustion is detected, as the complex interactions of oxygen and unburned fuel can lead to flammable mixtures igniting further down from the burners. Such conditions can lead to a number of negative process control conditions, including excess heat at the process tubes, which causes damage and leaks; carbon deposits on the process tubes, which decreases efficiency and heat transfer; and, in extreme cases, potentially dangerous combustion events can occur.

However, if a process problem is detected either by analytical instruments or other safety devices, it is inadvisable to simply switch off the fuel supply to the burners. Abrupt stops, restarts and light off conditions are the most common time for furnace incidents to occur. It is safer to bring the process carefully and correctly under control than to fully shutdown and restart the process and, as such, good quality and comprehensive analysis of the products of combustion, or lack of, is vital.

Despite the risks, there are measureable rewards for operating fired heaters at Low Excess Air (LEA) levels. In LEA combustion control the lowest level of fuel is consumed and the products of combustion are cooled the least by unused excess air. The cost benefits of these efficiencies are considerable, with just a single percentage saving in fuel enabling savings of millions of rands per year.

Controlling air levels just above the point at which incomplete combustion starts also enables the ‘cleanest burn’, helping plants meet environmental emissions requirements. This reduces the emission of NOX, created when unused oxygen reacts with nitrogen from the combustion air. A competent LEA combustion process – running at approximately 2.5-5% excess air or 0.5-1% oxygen above the point at which unburned fuel in the form of carbon monoxide starts to breakthrough – can be maintained and controlled at the most efficient running point. If the process is run with too little air, the products of combustion will contain unburned fuel which is wasted and passed into the atmosphere. As soon as there is not enough air to allow full combustion of the fuel, the process will quickly degenerate into an unsafe condition. Pockets of carbon monoxide, and possibly hydrogen and methane, can travel through the process, causing localized hot spots as they ignite and produce higher emissions of gases such as carbon monoxide. These effects begin to manifest at less than 10-15% excess air or 2-3% oxygen in the flue gas, with burner.

Excluding extractive techniques used for portable gas analyzers and some highly specialist fixed gas analyzer applications, there are currently two very different technologies available to measure the level of unused oxygen in the fired heater combustion process. Zirconium oxide cell technologies – commonly known as Zirconia – have been established for more than 50 years but have recently been challenged by the introduction of Tunable Diode Laser analyzers (TDL). Both offer distinct advantages and disadvantages in their usage, so it is extremely important to understand their respective qualities to deduce which is most suitable for an application.

Neither offers a ‘one-size- fits-all’ solution, but there are notable advantages to be gained by using them as complementary techniques.

SERVOTOUGH Fluegas Exact 2700

As this type of system can be installed close to the burners, the ‘lag time’ for oxygen analysis – the measurement delay due to sensor response – is minimized, giving operators a comparatively short response time. Detailed burner performance can be also monitored by installing multiple analyzers across banks of burners; this is especially important in fired heaters where low NOX burners are fitted, as the burners are notoriously difficult to evaluate through visual inspection as the flame is non–luminous. The outputs of these analyzers can then be averaged to give oxygen trim control. Many systems also offer the option of fitting an additional carbon monoxide or combustibles catalytic sensor. This offers additional diagnostic benefits for process and burner optimization, including providing early indications that excess air levels are too low, or that a bank of burners is incorrectly set–up, adversely affected by other burners or suffering from nozzle blockage.

Flame traps should always be specified when choosing this type of analyzer system to prevent the sensors from becoming a source of ignition back to the process. Care should then be taken to ensure that the flame traps have little effect on measurement lag times.

Critically, when flame traps are fitted to an in-situ technique, the lag time can be up to several minutes, which many engineers will consider too risky for safe control. Problems can be compounded far from the burners to limit process temperature effects on the sensors, then both air ingress into the flue and delays caused by the distance from the burners can weaken the ability to control the process efficiently and safely. The longer the analysis lag time and greater the air ingress, the further the process excess oxygen levels have to be controlled away from the ideal LEA point, as a high safety margin is then required to prevent incomplete combustion. Consequently, engineers must have a clear understanding that their processes will be compromised by the potential shortcomings of in-situ techniques, regardless of the initial installation cost benefits that they offer.

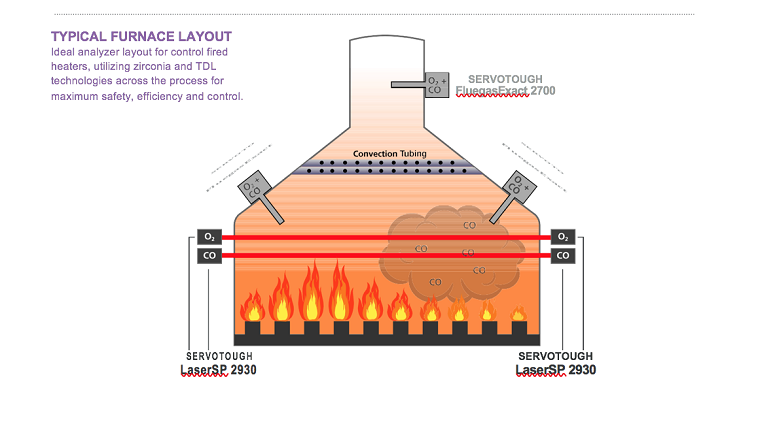

In a typical fired heater, the optimum analytical techniques for process control, efficiency, safety and emissions reduction are a mix of zirconia and TDL technologies applied to specific locations.

Minimum of two zirconia analyzers placed at the top of the radiant section, or at the very least bottom of the convective section, is essential: analyzers at these locations will minimize lag times and air ingress, enabling an average measurement and providing back-up when one analyzer requires maintenance. For LEA operation, a combustibles sensor combined with the zirconia analyzer is a very cost-effective choice, the installation of which will support process safety procedures and site safety regulations. Addition of an integrated flow alarm also enables preventative maintenance.

Levels of carbon monoxide and water within the radiant section can be effectively measured by TDL in conjunction with zirconia for oxygen. For flameout protection and diagnostics, and for added combustibles breakthrough analysis, an additional combined CO/methane TDL can be used.

This TDL should be located as close to the burners as physically possible.

While TDL will continue to improve, it is not yet ready to completely displace the older technologies of zirconia and catalytic sensors within combustion control. Within the short to medium term, it seems more likely that its introduction will trigger a new generation of zirconia and catalytic sensor improvements and analyzer developments. This competition between technologies will ultimately benefit process engineers and operators, as it will help generate new, cost effective and reliable instrument solution.