(DLG). Electromobility is not only increasingly important on the road but also in the off-highway sector. The leading technology suppliers are consistently driving electrification with integrated system solutions. The full potential of mobile machinery and commercial vehicles will be on display from 12 to 18 November 2023 at SYSTEMS & COMPONENTS, which is scheduled to take place in parallel with Agritechnica. The exhibitors at the exhibition grounds in Hanover, Germany, will be presenting diverse hybrid concepts as well as 100 percent electric drive solutions – for virtually every segment.

Innovations in drive technology for mobile machinery used to be based on diesel engines and hydrostatic drives but today’s focus now lies with electrification. Looking ahead to SYSTEMS & COMPONENTS 2023, it can be recognised that the trend towards electromobility is no longer limited to passenger cars but also plays a central role in agriculture and forestry, as well as construction and mining, further increasing the productivity of mobile machinery. The advantages of electric drives are obvious, containing fewer moving parts and needing less frequent servicing than combustion engines, as well as offering higher efficiency, reduced emissions and increased performance.

However, the increasing size and complexity of the systems are presenting developers with a challenge. Simply electrifying the drivetrain by, for example, replacing the diesel engine with an electric motor, falls short as a potential solution. Mobile machinery, be it an excavator, a dumper truck or a tractor, is invariably equipped with hydraulic systems that, in the best case, should also be electrified. Alternatively, the diesel engine could become part of a hybrid drive or the vehicles could be equipped with battery-powered electric drives or diesel generators. Such questions have to be answered at the start of every electrification project.

Scalability from the modular system

Engineers and developers will find answers to these issues at SYSTEMS & COMPONENTS. The B2B platform will be focused on practicable solutions for electrification that are easy to integrate and, with pioneering driving and work functions, will lead to new business models. To achieve this, the technology providers are supplying installation solutions, customisable for application, operating area and engine output. From synchromesh, powershift and stepless gearboxes with corresponding electronic control systems, up to and including rigid and steering axles, the right equipment is available for every requirement.

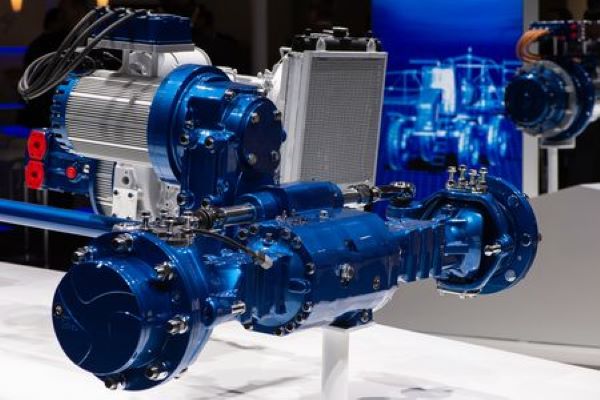

Modular platforms developed specifically for the off-highway sector, including not only electric motors and inverters, but also gearboxes, software and accessories as well as matching battery and hydraulic systems, will be shown. Compatible with a wide variety of designs, the performance range covers the entire spectrum from compact to heavy-duty working machines. The high voltage portfolio includes variable output motors designed to be used, for example, as generators in diesel-electric applications. With peak outputs of up to 400 kW and maximum torques of over 2,000 Nm, such motors offer the maximum possible design freedom for the electrification of new and existing vehicle architectures. Further key components, such as DC/DC converters and on-board chargers, will round off the range of products on display at the trade fair grounds.

Into the future with zero emissions

The increasing use of alternative drives in off-highway applications is also being encouraged by exhaust emission legislation. In some cases, the strict European Off-Highway Stage V and US Off-Highway Tier 4 regulations are compelling manufacturers to rethink their designs. Although exhaust emission technology is well understood, using electric drives eliminates the concern about tighter exhaust emission limits. The “eDumper” demonstrates how manufacturers are tackling this issue in a sustainable manner. Based on a Komatsu model HD 605-7, this dumper truck is not only thought to be the world’s largest electric vehicle, but, according to the manufacturer, it is also fitted with the highest capacity battery (700 kWh) ever installed in a vehicle. With a payload of 65 t, the truck can transport both limestone and marlstone from the quarry area to the transport system. While moving downhill, the electric motors slow the fully-laden vehicle and feed the resulting energy into the battery. The heavier the load, the more the vehicle needs to brake and the more electricity is recuperated. The energy stored in the batteries is then used for traveling uphill without a load.

The shifting of the market towards zero emission mobile machines and vehicles with battery and fuel cell drives is not only demonstrated by proof-of-concept vehicles such as the eDumper. Above all, technology partnerships with selected OEMs are paving the way to the zero emission construction site – an approach that machine and vehicle manufacturers are pursuing in parallel with the continuous development of their own solutions, and one that is intended to enable faster market launches. Depending on the customer’s requirements, diesel-powered wheel loaders, excavators or dumper trucks can be converted to electric drives. One example of this is the L120H Electric Conversion from Volvo CE, a 20-tonne wheel loader offering the same performance as its diesel counterpart, but with zero exhaust emissions and near silent operation. With a battery capacity of 240 kWh, it has an operating time of around five hours in medium-duty applications and can be fully recharged within two hours.

System optimisation through electrification

Agricultural machinery manufacturers are also continuously extending their portfolio of electric machines and are transforming the industry, moving it towards a climate-neutral future. High- and low-voltage generator systems for stepless tractor gearboxes are just some of the components that will be on display at the exhibition grounds in Hanover. However electrification is not limited to the drivetrain. Hydraulic drives currently control linear actuation in agricultural machinery but electric actuators are increasingly gaining in importance. To achieve the necessary performance breakthrough for tractors and attachments, focus is increasingly shifting to modular electric drive systems with which synergies can be achieved with other applications. Increased efficiency and reduced wheel slip are some of the optimisation objectives of electrically distributed traction management.

John Deere is showing the form that this can take with eAutoPowr – a stepless gearbox that replaces hydraulic with electrical components. This gearbox with electromechanical power split is available for three tractor model series. The electrical system is powerful enough to not only supply the electric motor, but can additionally provide up to 100 kW for external consumers via 480 V variable-frequency three-phase alternating current. John Deere has developed an initial application together with the Belgian agricultural machinery supplier Joskin. In combination with a slurry tanker drive, two axles are driven electrically and the weight of the tanker is used to transfer tractive power, leading to increased traction, less slip and better track guidance. Speeds of up to 5 kph are 100 percent electric, enabling fast and smooth changes of direction. The driver also benefits from precise speed regulation and improved acceleration behaviour.

The optimum drive strategy for every need

The performance of modern off-highway vehicles requires reliable and precise engine operation. Battery energy densities are currently too low to permit the replacement of the combustion engine in all applications. But the future belongs to pioneering hybrid concepts, combining smaller and lower-emission diesel engines with electric drives and lithium-ion rechargeable batteries. In this context, open systems will be a key point at SYSTEMS & COMPONENTS 2023. From 12 to 18 November, commercial vehicle engine developers and design engineers will find diesel, gas, hybrid, electric and hydrogen technologies for the best possible customer solution for each application at the trade fair grounds in Hanover.